-

1) What is capacity of a battery?

-

2)Factors affecting the capacity of lithium ion batteries+

- 1. Energy Density

- 2. Anode Materials

-

3) High capacity 12v battery

-

4) Highest 18650 capacity

-

5) Highest 26650 capacity

-

6) high capacity battery pack

-

7) Why do lithium ion batteries lose capacity?+

- 1. Overcharge

- 2. Electrolyte Decomposition (Reduction)

- 3. Impact of self discharge

- 4. Temperature Conditions

High Capacity Lithium ion Battery Manufacturer,Recommend Battery

Nov 28, 2019 Pageview:4085

1) What is capacity of a battery?

Battery capacity refers to the amount of power that can be stored in the battery, which is one of the important performance indicators to measure the battery performance. It represents the amount of electricity released by the battery under certain conditions (discharge rate, temperature, final voltage, etc.) (js-150d can be used for discharge test), that is, the battery capacity.

2)Factors affecting the capacity of lithium ion batteries

Lithium ion battery has four main parts, including anode, cathode, separator and electrolyte. The capacity of lithium ion battery mainly depends on the quality and ratio of active materials of anode and cathode, which determines the energy density of battery.

Battery capacity = energy density × battery volume

With the same volume, the capacity of lithium battery is determined by the energy density, and the energy density of lithium battery is mainly determined by the anode material. Most of the time, energy density value rankings are as following: ternary material of nickel-cobalt-manganese > lithium cobalt oxides >lithium iron phosphate > lithium manganese.

1. Energy Density

Energy density is the amount of energy stored in a given space or mass. The energy density of a battery is the amount of power emitted per unit of volume or mass.

Energy density of battery weight = battery capacity × voltage during discharging/weight, the unit is Wh/kg(watt-hour /kg)

Energy density of battery volume = battery capacity × voltage during discharging/volume, the unit is Wh/L(watt-hour/liter)

The greater the energy density of a battery, the more energy is stored per unit of volume or weight.

The energy density of the battery is basically determined by the anode and cathode materials, but the active materials of anode and cathode cannot guarantee that battery can generate electricity. It still needs a lot of inactive substances, such as diaphragm, electrolyte, shell and fluid, etc.

Capacity, compacted density, voltage platform and structural stability of anode materials

Capacity, compacted density and voltage platform of cathode materials

Thickness and porosity of diaphragm, etc.

Shell thickness

Amount of electrolyte

Conductivity, thickness and density of current collector

Production technology level

According to Made in China 2025, the development plan of power batteries is defined as follow: In 2020, the energy density of battery will reach 300Wh/kg; In 2025, the energy density of the battery will reach 400Wh/kg; In 2030, the energy density of the battery will reach 500Wh/kg.

2. Anode Materials

Anode material is the only or main supplier of lithium ion in lithium ion batteries. It is also the bottleneck to improve the energy density of lithium-ion batteries. Due to the high requirement of lithium ion batteries for anode materials, there are few materials that can be used as (or are expected to be used as) anode materials for lithium ion batteries. The following are the characteristics of several anode materials for lithium ion batteries:

Characteristics of Anode Materials for lithium ion batteries

| Item | LiCoO2 | LiNiCoMnO2 | LiMn2O4 | LiFePO4 |

| Compacted Density(g/cm3) | 2.8~3.0 | 2.0~2.3 | 2.2~2.4 | 1.0~1.4 |

| Specific Surface Area(m2/g) | 0.4~0.6 | 0.2~0.4 | 0.4~0.8 | 12~20 |

| Gram Volume (mAh/g) | 135~140 | 140~180 | 90~100 | 130~140 |

| Voltage Platform (V) | 3.7 | 3.5 | 3.8 | 3.2 |

| Cycle Performance | ≥500 times | ≥500 times | ≥300 times | ≥2000 times |

| Transition Metal | little | little | a lot | abundant |

| Material Cost | very expansive | expensive | cheap | cheap |

| Environmental Protection | contain Co | contain Ni and Co | non-toxic | non-toxic |

| Safety Performance | bad | good | better | best |

| Scope of Application | small and medium size battery | small batteries/small power battery | power battery, low cost battery | power battery/power supply with super capacity |

On the other hand, although the capacity improvement of lithium ion batteries is limited by anode materials, the research on anode materials and the improvement of energy density are far from the end. Through the development of related fields and breakthrough of some limitations, it is possible to improve the specific capacity and energy density of lithium ion battery anode materials.

3) High capacity 12v battery

12V large-capacity battery refers to the battery whose nominal voltage is 12V and the battery capacity exceeds 20,000mAh. That's what we call a 12V lithium battery. Some batteries can hold as much as 20AH, or 50AH. The more cells are connected in parallel, the larger the capacity is.

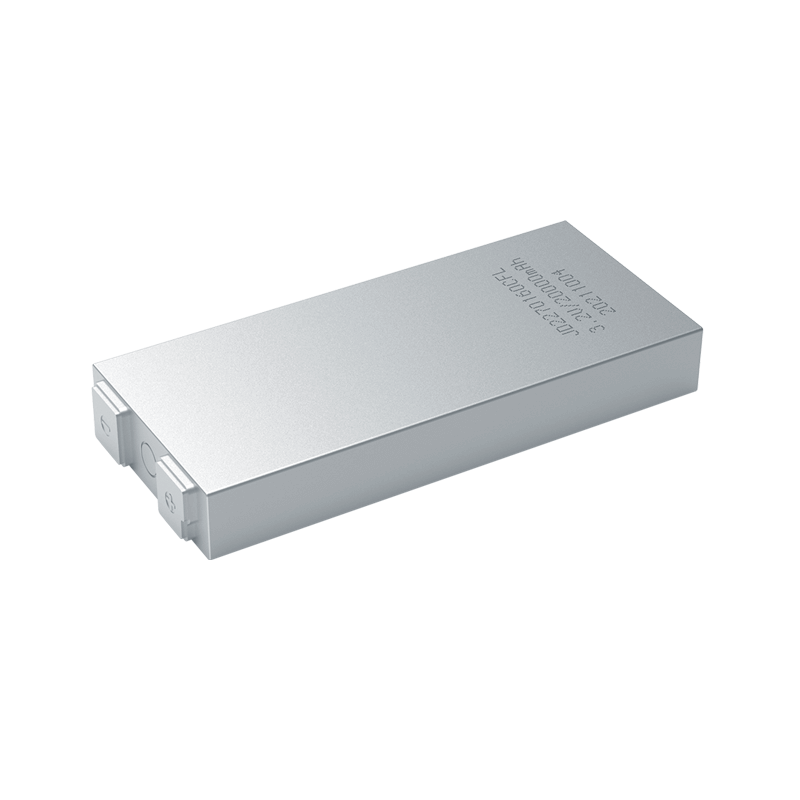

Dongguan Large Electronics Co., Ltd. is a well-known manufacturer of 12V large-capacity battery in China. The voltage, capacity, size, shape and function of lithium battery can be flexibly customized to meet customer needs. Here is a customized version of the company's large-capacity 12V lithium battery:

12.8V 60Ah 26650 Large-capacity LiFePO4 Battery Pack

Product number: 04EQ226-01

Cell model: 26650/4S18P/12.8V/60Ah

Nominal voltage:12.8V

Nominal capacity:60Ah

Charging temperature:0~45℃

Discharging temperature: -20~50 ℃

Product dimension: 290×220×110mm(Max)

Battery weight: 7.6Kg

Protective function: short circuit protection, overcharge protection, over-discharge protection, overcurrent protection, temperature protection

Product features

Shock-resistant: fill in the shock-resistant structure inside the cold rolling metal plate housing to satisfy the requirements of good security and high reliability.

Salt-spray proof: Spray the surface with powder to resist salt spray mold, which is suitable for marine working environment.

Communication management: Adopt software management chip, precise data transmission and accurate temperature control so as to try our best to eliminate the security risks.

Safety management of the battery: when the temperature probe of battery finds out over temperature status, the protection system is on automatically.

The battery pack has long cycling life, which conforms to the principle of low carbon, energy conservation and environmental protection.

4) Highest 18650 capacity

Due to the fixed size of 18650 lithium battery, its maximum capacity has been concerned by many practitioners. In recent years, various manufacturers have improved their technologies, and the product capacity has also been increased correspondingly. Samsung, Panasonic, LG, SONY and Toshiba can achieve more than 3600mAh. However, the stability and consistency is not good, and is temporarily unable to form the mass production trend.

At present, the good-quality 18650 lithium battery capacity in the market is between 2200 and 3500mAh, and the 18650 lithium battery in this range has the best stability and consistency.

5) Highest 26650 capacity

What is the capacity of 26650 lithium battery? Let’s talk about two current domestic popular material systems.

lithium iron phosphate material system: IFR26650 lithium battery has 3000mAh, 3200mAh, 3300mAh, 3500mAh, 3800mAh and other capacity, and its nominal voltage is 3.2V. At present, the largest capacity of 26650 lithium battery on the market is 3.2V 3500mAh.

Ternary (nickel-cobalt-manganese) material system: The general capacity of ternary INR26650 lithium battery in the market is 5000mAh, 5500mAh or 6000mAh.

6) high capacity battery pack

Large-capacity lithium-ion battery pack is composed of several 3.7V lithium batteries in series and in parallel to meet the requirements of high voltage and high capacity for different equipment. The larger the number of cells in parallel, the larger the capacity of the assembled battery has.

Lithium batteries connected in parallel: The battery pack has constant voltage, while battery capacity increases, internal resistance decreases, and the power supply time is extended.

Lithium batteries connected in series: Voltage increases, but the capacity does not change.

General lithium batteries connected in parallel or in series need lithium cell matching. Here are the matching criteria: voltage difference of lithium cell≤ 10 mV, internal resistance difference of lithium cell ≤5mΩ, capacity difference of lithium cell≤20mA

18650 11.1v 40Ah Large-capacity lithium battery of Petroleum Exploration Equipment

Product number: 05BQ1413-06

Cell model:18650-3S16P/40Ah/11.1V

Nominal voltage:11.1V

Nominal capacity:40Ah

Charging temperature:0℃~+45℃

Discharging temperature: -20℃~+60℃

Product dimension: 226×151×84mm

Battery weight: 3kg

Product feature: waterproof/dustproof IP67, fireproofing 94-V0

7) Why do lithium ion batteries lose capacity?

1. Overcharge

The overcharge reaction of graphite cathode

When the battery is overcharged, lithium ions tend to be reductively deposited on the surface of the cathode, and the deposited lithium is coated on the cathode surface, blocking the embedding of lithium. This leads to discharge efficiency reduction and capacity loss.

Overcharge reaction of anode

When the ratio of anode active material is lower than that of cathode, the anode may overcharge.

The capacity loss caused by overcharging of anode is mainly due to the production of electrochemical inert substances (such as Co3O4, Mn2O3, etc.), which destroys the capacity balance between electrodes, and the capacity loss is irreversible.

The oxidizing reaction of electrolyte during overcharging

When the voltage is higher than 4.5V the electrolyte will oxidize and form insoluble substances (such as Li2Co3) and gases. These insoluble substances will stop the migration of lithium ions in the micropores of the electrode, resulting in capacity loss during the cyclic process.

2. Electrolyte Decomposition (Reduction)

-- Decompose on the electrode

Electrolytes decompose on anode:

Electrolyte consists of solvent and supporting electrolyte. It will produce insoluble products Li2Co3 and LiF after the anode decomposition. Decrease the porosity of the electrode and reduce the battery capacity, electrolytic reduction reaction will affect capacity and cycling life of the battery. Besides, due to the reduction of produced gas, battery internal pressure may increase, resulting in security issues.

Electrolytes decompose on cathode:

Electrolyte is not stable on graphite and other lithium carbon cathode, which is easy to produce irreversible capacity. During the initial charge and discharge process, the electrolyte decomposition will form a passivation film on the surface of the electrode, and the passivation film can separate the electrolyte from the carbon cathode to prevent further decomposition of the electrolyte, so as to maintain the structural stability of the carbon cathode. The reduction of electrolyte under ideal conditions is limited to the formation stage of passivation film, which won’t happen again after the cycle is stable.

-- Reduction mechanism of electrolyte

Solvent reduction

The reduction of PC and EC consists of an electron reaction and a two-electron reaction process. The two-electron reaction produces Li2CO3: in the first discharge process, when the electrode potential is close to O.8V(vs.Li/Li+), PC/EC hass an electrochemical reaction on graphite, producing CH=CHCH3(g)/CH2=CH2(g) and LiCO3 (s), resulting in irreversible capacity loss on the graphite electrode.

Reduction of electrolyte

Electrolyte reduction is generally considered to be involved in the formation of carbon electrode surface film, so the type and concentration of the electrolyte will affect the performance of carbon electrode. In some cases, electrolyte reduction contributes to the stabilization of the carbon surface, resulting in the required passivation layer.

It is generally believed that the supporting electrolyte is easier to be reduced than the solvent, and the reduction products are mixed with the cathode deposition film, which will affect the capacity attenuation of the battery.

3. Impact of self discharge

Self discharge refers to the phenomenon of natural loss of capacity of battery in unused state. There are two conditions will lead to lithium ion battery self discharge: reversible capacity loss and irreversible capacity loss.

Irreversible capacity loss refers to capacity loss that recovers during charging, while the irreversible capacity loss on the contrary. Anode and cathode may have micro-battery function with electrolyte in the charging status, embedding and disembeding lithium ion only relates to the lithium ion of electrolyte, so there is no balance between capacity of anode and cathode. The capacity loss during charging cannot recover.

4. Temperature Conditions

Temperature mainly affects the activity of the internal plate materials and electrolyte properties. High temperature and low temperature have a great impact on the capacity of the battery.

Lithium ion battery at low temperature significantly has lower activity of the battery. The capacity of lithium embedding and disembedding decreases, the battery internal resistance and polarization voltage increases, the actual usable capacity reduces, battery discharge capacity descends, discharge state is not so good, the battery is more easy to reach discharge cut-off voltage, the battery capacity goes down, and the battery energy use efficiency declines.

Similarly, lithium ion battery under high temperature environment, lithium ion embeds and disembeds actively between anode and cathode. Battery internal resistance reduces, thereby the internal resistance is stable for longer hour, which makes electron transport number in the external circuit increase, then the battery will have larger capacity. However, if the battery works in a high temperature environment for a long time, the stability of the anode lattice structure will become worse, the safety of the battery will reduce, and the cycling life will significantly shorten.

Therefore, temperature conditions have a certain impact on the capacity of lithium ion batteries. However, in practical applications, we can ensure that the battery can work at a suitable temperature by increasing the electric heating management of the battery, so as to make sure that the capacity of the battery can reach the normal standard as much as possible.

- Prev Article: Where Can I Recycle Lithium Batteries?

- Next Article: Puffed LiPo Battery Disposal Analysis

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News