How to Make Batteries in Medical Devices More Reliable

Mar 12, 2020 Pageview:1654

Nowadays, the approval process is getting tough to release a new product in the pharmaceutical industry. The new rules have come up that increases the costs of the manufacturing unit and have complicated process.

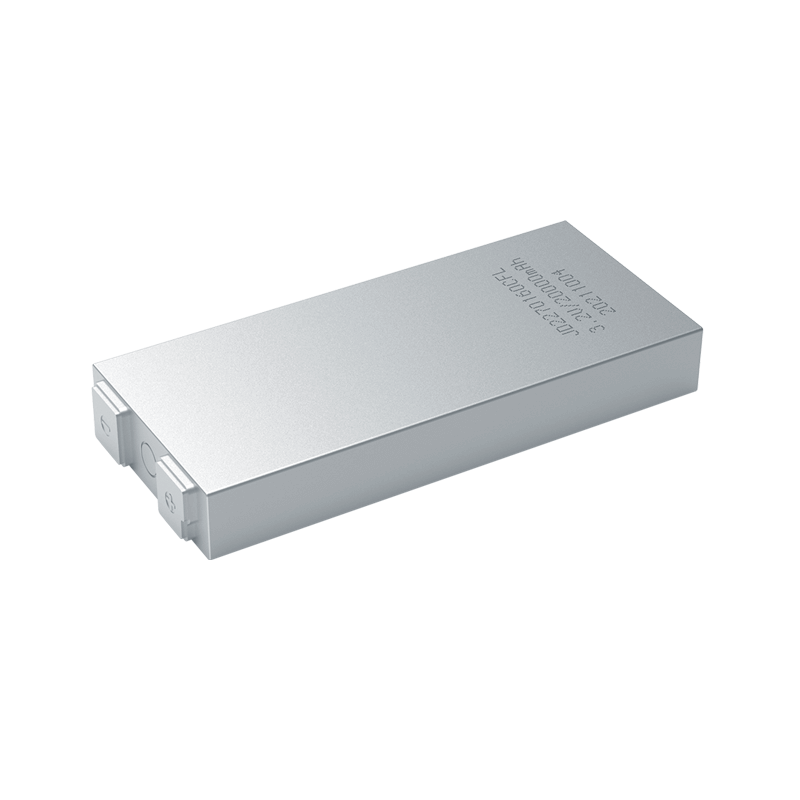

Batteries are essential components of medical devices. As the instruments are getting computerized and technology is getting increased, their system performance and reliability depend on the battery. So that is why continuous improvement is required in the battery.

What features do battery needs in medical devices?

If you talk about the features, there are a lot of features that are listed. The features allow medical devices to work efficiently. Some of the features are:

Energy Density – it is a measure of how much energy the battery can store in a given mass or size. So a battery with high energy density can easily power the load for longer with low energy density.

Power - It is the amount of energy that is stored in the battery. It is expressed in watt-hours. A watt-hour is a voltage that the battery provides, which is multiplied by the current in the battery.

Voltage – The difference in electric potential between the positive and negative terminals of the battery.

Pulse Amplitude – It provides the immediate pacemaker longevity gain.

Passivation – It allows the battery to have a very low self-discharge rate and long shelf life. After applying the load to a cell, the high resistance of the passivation layer drops rapidly.

Self Discharge – The batteries that are stored in lower temperatures, thus reduces the rate of self-discharge and preserves the internal energy stored in the battery.

Temperature Range- If you operate battery at a different temperature will improve the romance dance.

High-Temperature Performance - The chemical reaction becomes faster, and more current is produced, and life of battery shortens.

Low-Temperature Performance – The chemical reaction slows down, and a smaller current is produced, but the battery can last longer.

Operating Life- It determines the durability of the battery.

Medical Applications- Lithium-ion batteries used in devices such as Bone Healers, Oxygen Meters, Glucose monitor defibrillator etc.

Does lithium-ion battery have sufficient quality assurance for medical devices?

If you are looking to meet the quality assurance for medical device, you need to get through the approval process, It satisfies the present moment but ignores the tolerances in battery performance and capacity losses that develop over time.

In the routine quality check, the manufacturers check only the voltage and internal resistance of a cell battery capacity, and the leading health indicator is omitted. Capacity assessment is complex, and measurement by a discharge cycle is prohibitive.

EIS stands for Electrochemical impedance spectroscopy offers trustworthy solutions in estimating capacity and detecting problems. This is a particular interest for battery manufacturers, and close collaboration will be essential to examine the battery faults by EIS. Today the companies like Cadex developed multi-model electrochemical impedance spectroscopy. It can read battery capacity non invasively. Matrices need to be prepared for each battery to check each battery or cell. The test is of 15 -30 minutes that makes it possible.

The FDA is where you get to know solutions for battery problems and has noted that some implant batteries provide less than the estimated run time, hinting to manufacturing problems.

A low battery may show itself as weariness in the patient. Doctors are prepared to analyze clinical indications and are less acquainted with the impact of a fading battery. There is additionally a situation where an embed battery shorted and consumed the tissues of the patient. As we rely increasingly more upon batteries for our prosperity, quality control, and utilizing advance technologies, it will reduce risk and medical costs.

Do you have enough knowledge of integrating batteries in medical devices?

The medical institutions are concerned that the device manufacturers do not place sufficient importance on battery aging. There is not any uniform consumption model that exists in capacity.

Environmental conditions add more complexity to knowing the batteries. Safety is a big concern during the battery life that still needs attention.

Batteries have the best performance under room temperature and live longest when you use it moderately. One of the reasons the smart cells have more benefit is that it displays the remaining charge.

If you want to maintain accuracy, a smart battery needs regular maintenance to sort the tracking error between the chemical and digital battery. Calibration should be done every three months after forty partial cycles. If the device applies a deep discharge on its own accord, no additional calibration is required.

Even after it gets sealed, some cells include vents to release gases that are formed during exposure to stressful conditions. The electric toothbrush was an example instead of venting. The engineers made a waterproof device, and they did not know that an alkaline battery produces some gases during discharge. The accumulated gases inside the toothbrush have led to the explosion.

The other example is of Boeing B787 Dreamliner battery, where the battery behavior was overlooked. Engineers have estimated that smoke events on the Li-on battery could occur once in 100,000 flight hours. The battery notification involves the chain reaction that consists of the overheat.

If you place the battery in a steel container then it is capable of withstanding a fire without damaging the nearby areas and adding a one way to vent to release gas from the burning battery, it is a good learning experience for medical devices.

Conclusion

Batteries diagnostics are not as advanced as other technologies, but progress is being made further. Experts assume that EIS will lead the research, and the results will be performed in laboratories. The growing number of paramedics is also an approach toward battery maintenance. The increase in risk management and reducing the environmental impact of discarding batteries is an added benefit. The use of new innovative technologies and research in the battery will make a drastic change in medical devices.

- Prev Article: 18650 Battery Jump Starter-Methods and Buying

- Next Article: How Long Do We Need To Change A Medical Lithium-Ion Battery?

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News